σtrue =

F/A = (F/A0) (1+εeng) = σeng(1+εeng)

εe = σ/E

| True Strain | True Stress (N/mm^2) | Tr Stress | Elastic Strain (εe) | Plastic Strain (εp) |

| 0 | 0 | 0 | 0 | 0 |

| 0.001 | 200 | 200.2 | 0.001001 | -1e-06 |

| 0.002 | 400 | 400.8 | 0.002004 | -4e-06 |

| 0.003 | 600 | 601.8 | 0.003009 | -9e-06 |

| 0.004 | 800 | 803.2 | 0.004016 | -1.6e-05 |

| 0.0055 | 900 | 904.95 | 0.004525 | 0.000975 |

| 0.008 | 1000 | 1008 | 0.00504 | 0.00296 |

| 0.0125 | 1100 | 1113.75 | 0.005569 | 0.006931 |

| 0.026 | 1200 | 1231.2 | 0.006156 | 0.019844 |

P = [0.8(2t)σy]/OD

P = 12.8 MPa

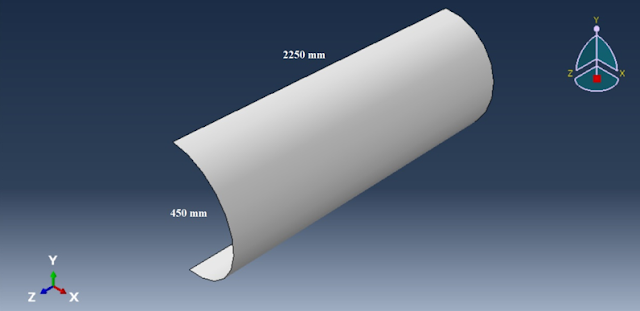

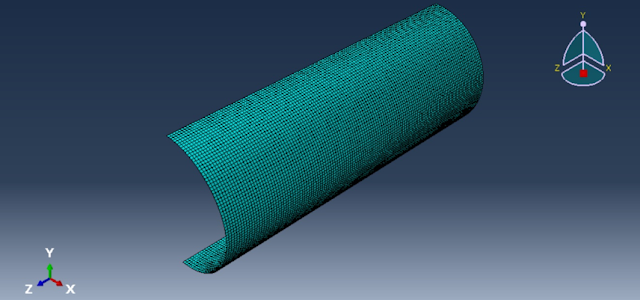

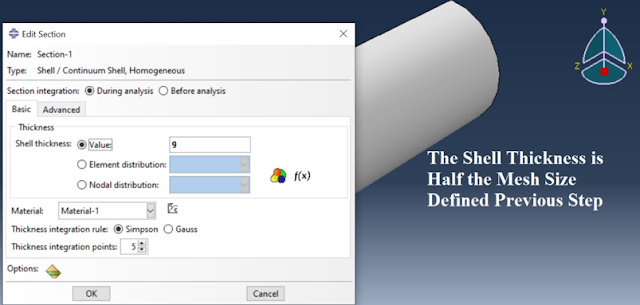

Meshing

Next, we create the mesh. The mesh size is set to 18 mm, which is twice the size of the shell thickness.

Setting Material Properties

For the elastoplastic behaviour, the following material properties are given:

Creating Steps with Loads and Boundary Conditions

In this step, we define the boundary condition (BC) and load. A reference point (RP) is created to fix one end of the pipe. For the RP, a rigid body constraint is defined. Three BCs are generated as follow:

BC-1: for symmetry about X-axis

BC-2: for symmetry about Z-axis

BC-3: for the reference point (RP1), which is fixed along the axes.

Then, a pressure load of magnitude 12.8 MPa is applied inside the pipe.

Results and Discussions:

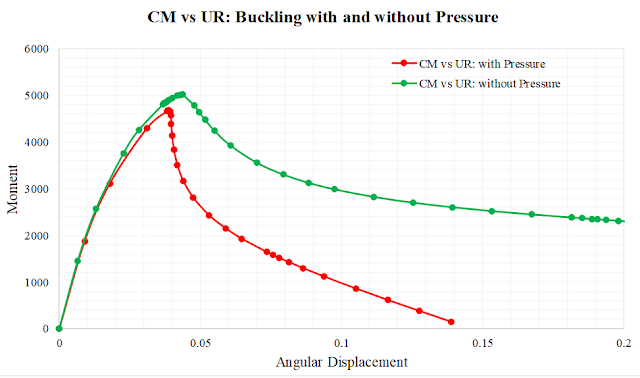

Since the model is created with necessary boundary conditions and loads, in this section, we are interested to consider two circumstances.

• Buckling when both pressure and bending are considered

• Buckling when bending is considered without pressure

We apply the static Rik’s approach as a force control. The following figure shows the Von Mises stress when only pressure is applied inside the wall of the pipe.

Buckling when both pressure and bending are considered

At first, we apply a moment of 5x10^10 Nmm at the reference point by creating a new step where Rik’s static algorithm is selected. In this scenario, the pressure is still present inside the pipe. The following figure demonstrates the three steps for the simulation.

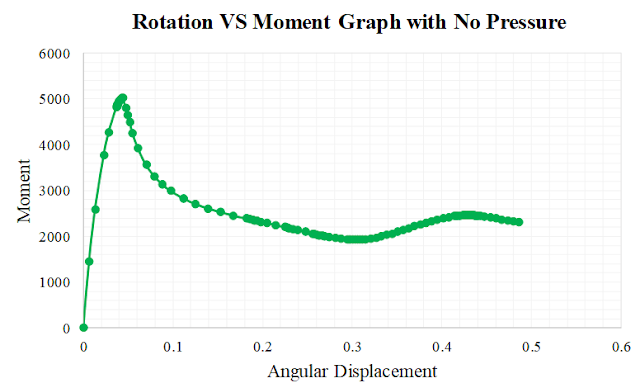

Buckling when bending is considered without pressure

In this step, we just suppress the load leaving all other conditions same. We are interested to see the effect of the bending only on the buckling rate of the pipe.

|

| Showing 2 steps: no pressure (left), and with angular displacement (right) The following figure shows two relationship when pressure is absent: moment vs arc length and rotation vs arc length. The intersection point between two graphs in the figure is the convergence point for the simulation. |

|

| Showing relationships between moment and arc length, and rotation and arc length without pressure |

|

| Moment without pressure (left) and rotation without pressure (right) when arc length is 0.8016 mm |

The following plot shows the relation between moment and angular displacement when pressure is absent in the pipe.

From the following comparison, we see that the buckling is higher when there is no pressure than the buckling with internal pressure.

nice info!! thanks

ReplyDeletevisit mine: muhammad solehuddin https://uhamka.ac.id/

thanks for sharing

ReplyDeleteUMJ Keren

thanks for sharing

ReplyDeleteUMJ Keren

Could you please extend them a little from next time?

ReplyDeleteThank you for the post.

Signed By : Kampus terkemuka

Could you please extend them a little from next time?

ReplyDeleteThank you for the post.

Signed By : Kampus terkemuka